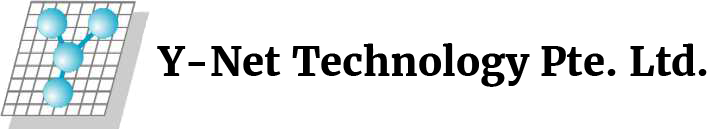

OKI-FORT offers a complete range of fiber optic cables, from Indoor, Duct grade to Outdoor.

Key Features

Moisture Protection without Jelly Fill-In Compound

- UV Cured Hermetic Coating HF™

- Water-Proof 900µm or 2.8 mm sheath

- Polypropylene inner sheath

- Possibility of incorporating a water-absorbent tape for highly exposed cables

Cable Armouring

For Outdoor cables, OKI-FORT offers various options for metallic and non-metallic armoured cables:

For Outdoor cables, OKI-FORT offers various options for metallic and non-metallic armoured cables:

- Corrugated steel tube, corrugated aluminum tube, double steel tape and Lead sheath

- It’s unique non-metallic armoured cable (CHEMALLOY® + fiber glass) not only offer added protection from lightning strike, but also offer cost reduction and ease of installation as no grounding is required.

Peripheral Strength Members

All OKI-FORT outdoor cables are fitted with fiber glass or Aramid Strength members between the inner sheath and the cable’s outer jacket.

All OKI-FORT outdoor cables are fitted with fiber glass or Aramid Strength members between the inner sheath and the cable’s outer jacket.

- No need to free the central strength members to pull the cable

- Very easy cable termination

- Cable Jacket with high mechanical strength

- Easy installation of the cable by pull the outer jacket

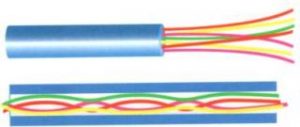

Crushing Protection

All OKI-FORT outdoor cables have at least two polymer sheaths. The polypropylene inner sheath provides additional crushing strength.

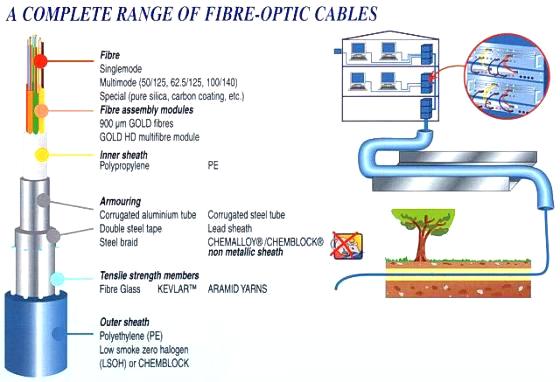

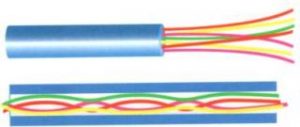

Loose Tube Construction

- The fibers are independent of the cable jacket

- Fibers are assembled in cable with excess length, therefore, the cable can withstand sheath elongation without stress on the fiber

- No risk of damaging fibers during cable installation

- Easy to prepare and strip

Outer Sheath

Indoor cables: Low Smoke Zero Halogen Jacket

- (BS 6425,VDE 0207, NFC 32-062)

- Fire-resistant (IEC 332 Part 1, NFC 32-070)

- PVC sheath – Does not propagate flame (UL 1666)

Outdoor cables: UV stabilized polyethylene jacket

- Hydrocarbon resistant PVC jacket